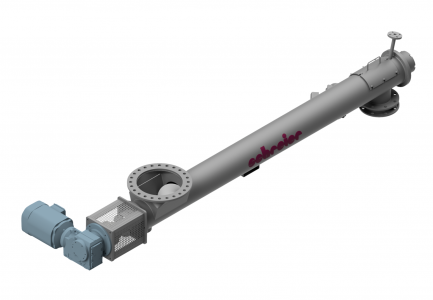

Screw feeders and screw conveyors

Precise feeding, discharging, filling, weighing and dosing – the bulk material and the task at hand determine the design, mode of operation, capacity and other performance features of screw feeders and screw conveyors.

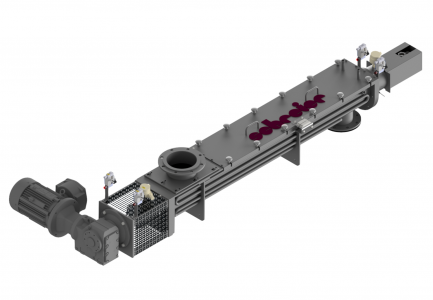

The basic equipment of screw feeders and screw conveyors consists of the inlet trough with dosing tool, the screw guide tube and the drive. An inlet hopper completes the basic equipment. It can be equipped with level indicators, cleaning opening, cover, inlets and other devices. Additional equipment required for bulk material (e.g. loosening) can be installed in the upper part of the inlet trough. The worm guide tube is arranged horizontally or rising, furthermore a downward conveying is possible product-specific. The screw guide tube and the screw conveyor can be heated, cooled or coated.

Continuous and discontinuous volumetric and gravimetric processes are implemented. Tailor-made solutions for the dosing requirements of the user. ![]() manufactures tubular and trough screw conveyors in robust industrial design. Spiral screw conveyors (with and without core) are also manufactured in-house according to the specific application. The smallest dosing machine has a spiral screw with 18 mm diameter. The maximum conveying capacity is 40 l/h at a bulk product weight of 1 kg/l.

manufactures tubular and trough screw conveyors in robust industrial design. Spiral screw conveyors (with and without core) are also manufactured in-house according to the specific application. The smallest dosing machine has a spiral screw with 18 mm diameter. The maximum conveying capacity is 40 l/h at a bulk product weight of 1 kg/l.

Depending on the cleaning interval, the complete screw conveyors can be “pulled” out of the storage for cleaning. For this purpose, ![]() manufactures special cleaning devices that make handling much easier. As seals, stuffing box packings, shaft sealing rings and plain bearings – with temperature sensor and purge air monitoring on request – have proven to be reliable. If a full-blade screw is used, the screw flights are continuously welded on both sides.

manufactures special cleaning devices that make handling much easier. As seals, stuffing box packings, shaft sealing rings and plain bearings – with temperature sensor and purge air monitoring on request – have proven to be reliable. If a full-blade screw is used, the screw flights are continuously welded on both sides.