Discharge stations

![]() discharge stations for bulk materials such as powder, granules, flakes or grains are manufactured according to customer and application requirements. Simple, semi-automated models and combinations are available for BIGBAGs, containers and bags.

discharge stations for bulk materials such as powder, granules, flakes or grains are manufactured according to customer and application requirements. Simple, semi-automated models and combinations are available for BIGBAGs, containers and bags.

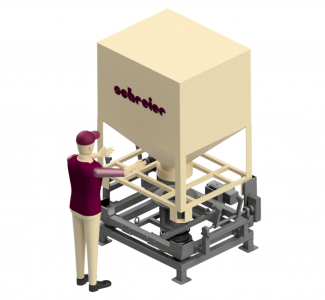

BIGBAG discharge station

Our discharge stations will be customized as a simple version for discharging of only one BIGBAG size and for different BIGBAG dimensions. The BIGBAGs are emptied with low dust levels and the product is fed into the subsequent process. The placement of the BIGBAGs is done by means of a fork lift truck or chain hoist. Automatic retightening units and discharge aids support the discharge of the product stream depending on the flow characteristics of the product.

Further equipment options

- lateral tightening of the BIGBAG by spring assemblies

- discharge aid rocker/walk-flow/vibrating table

- weighing technology and evaluation electronics

- chain hoist with power supply

- suction unit

- docking system (manual/pneumatic/hydraulic)

- reclosing device for partial emptying of BIGBAGs

- dosing device

- load lifting cross in different versions

- filling level indicator (capacitive, rotary wing)

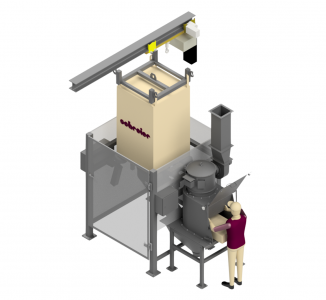

Container discharge station

Essentially, the ![]() container discharge stations consist of a spring-supported docking system with a receiving frame and a base frame which can be easily dismantled for cleaning.

container discharge stations consist of a spring-supported docking system with a receiving frame and a base frame which can be easily dismantled for cleaning.

Further equipment options

- emptying of different container dimensions

- dosing device

- weighing system and evaluation electronics

- attachment of a lump breaker

- attachment of a screw conveyor

- vibrating device on request with manual or automatic container clamping

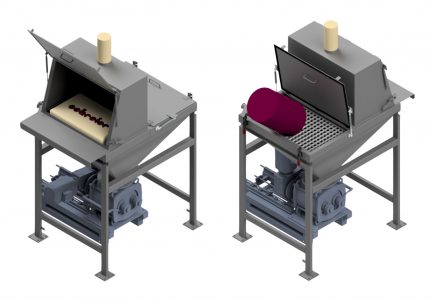

Bag discharge station

We manufacture sack discharging devices and stations individually according to your requirements. Starting with a support table with grating with or without hood, up to semi-automatic bag emptying.

For manual emptying, the sacks are cut open and emptied by hand with a knife. This is done either with the hood open or closed by means of built-in elastic gloves. The semi-automatic sack emptying is in contrast to this. Here the bags are opened by a pneumatic impact knife and the bag contents are then emptied automatically without manual intervention.

The volume of the storage container is also variable. On request, filling level limit switches can be used to display the available product quantity and thus provide information for the subsequent process.

Further equipment options

- top or standing filter

- shut-off or dosing device

- level limit switch

- empty bag compactor

- lump breaker or screw conveyor

Combination discharge station

Again and again we are faced with the challenge of having to empty different containers at one emptying location. In order to make this possible, we manufacture discharge stations for the most diverse package combinations: BIGBAG/sack, BIGBAG/container, container/sack, BIGBAG/container/sack and others. These combination stations have the advantage of being able to meet the different requirements of the subsequent processes (e.g. raw material A is required in large quantities, the addition of raw material B only in very small quantities). Combi stations are also very advantageous if there is not enough space available at the customer’s side.